|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Steam Solutions

Steam Solutions and the best steam equipment

Everything for a reliable and energy-efficient steam plant

Do your steam system problems occur regularly?

Whether it's frequent replacement or overhaul of your equipment or pressure and heat fluctuations,

KLINGER helps you troubleshoot and optimize your steam system.

With us you can:

- On-site troubleshooting

- Product Advisory

- Studies and audits of improvement potential

- Training your staff

Results:

- A safe steam system

- An efficient and stable production

- Less energy consumption

- Lower maintenance costs

- Service life improvement

- Shorter production batches due to faster warm-up times

Safe, efficient and worry-free use of your steam system.

In order to produce carefully, you are likely to place heavy demands on your steam system. We understand that like no other. In fact: we think you can get even more out of your steam system! By optimizing your steam system and ensuring your personnel are well-informed about its operations, you can enhance production efficiency while maintaining—and often improving—safety.

From advice to execution

Would you like to identify the improvement potential of your steam system for your multi-year plan? Do you outsource inspections because you lack time yourself? Would you like training for your staff because they lack knowledge or skills? At KLINGER you can count on all of these services. We work closely with Armstrong International, experts in the management of thermal systems.

There are numerous circumstances that can cause your steam system to stop functioning optimally. Changes in production, the load on the system, wear and tear, new techniques... The problems this causes are often unexpected and need to be fixed urgently. Our steam specialists will help you with first-line advice and the selection of equipment to solve the problems. This happens at your plant, since it is much more practical!

-

Valves

-

Double Isolation and Bleed (DIB) / Double Block and Bleed (DBB)

- - TVS3M

-

High Temperature Heat Pumps

- Hot water solutions

- Pumping trap Skids

- Flash tanks

- MTS-ThermoSyphon mixer

- The-Superheaters

- Tank Heaters

- Gaskets

- Liquid Drainers

- Air Vents

- Hoses

- Expansion Joints

- Level gauges

- (Spring loaded) safety valves

- Pressure gauges

- Vacuum breakers

Would you like to have more know-how in-house? We provide training courses to teach your staff skills or increase their knowledge. We can provide these trainings at your location or in our own training centers in Rotterdam, Elsloo, Velsen-Noord or Herstal (B).

- KLINGER Basic Steam and CondensateTraining | at KLINGER or on-site | 1 day

- Seminar KLINGER, Learning Center Herstal, Belgium | 2 days

- Seminar Armstrong Refining, Gas processing & Petrochemical Industries | Learning Center Herstal, Belgium | In English| 2 days

- Seminar Armstrong Food, Pharmaceutical & Light Industries | Learning Center Herstal, Belgium | In English| 2 days

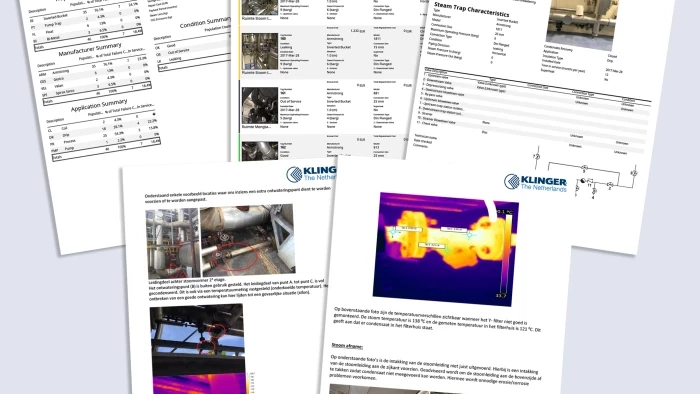

Steam trap surveys

An important element in the steam system is steam traps. Regular, proper checks of your steam traps help keep your production process optimal, increase safety and save costs. Our professionals will take the inspection off your hands. They will look at the dimensions and way the steam trap functions, as well as the steam system in front of it and the condensate system behind it.

Reports

from Armstrong International

Armstrong International also offers a software program in which you can easily track current data on your steam traps. In addition, the program calculates losses from leaking steam traps. So you always have up-to-date information for annual reports, multi-year plans, monthly statements or sustainability reports, for example.

Audits

Are you curious about the overall status of your steam system? We conduct audits to accurately identify the potential for improvement: how are the various subsystems doing, what hidden problems do we identify, and what improvements are possible?

KLINGER Survey Steam Traps (Steam trap inspection).

- SAGE data base, losses quantify

- Collecting information in the field

- Supplemental advisory report with comments steam & condensate system.

Trouble Shooting

Research steam & condensate optimization - KLINGER Walk Trough

Armstrong Audit often steam and condensate systems

Armstrong Thermal Assessment of the cold & heat flows

- possibly in combination with/ followed by Pinch Analysis

- possible feasibility studies /Circular Thermal/Heat Pump

Armstrong De-carbonization Study (Minimize, Optimise, DeCarbonise)

Whitepaper

Read our white paper on Steam surveys

Discover the benefits of regular checks of steam traps within steam systems.

Still a substantial part of Dutch natural gas is used to generate steam for applications in the industry. Innovations and upgrades of steam systems are the order of the day. This requires specialists who monitor the quality of the systems and transfer knowledge.

KLINGER's survey programs for entire installations, as well as steam traps are unique in this regard. Read our white paper on how to stay ahead cost-effectively with safe steam systems.

Frequently asked questions (FAQ)

I have a specific question

For more information about our steam solutions, please contact:

Demian Nouwens

Product Specialist Energy Management, Steam Solutions