|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

HOSE MANAGEMENT

Hose Management

Your hose assortment visualized; no more worries about testing and certifications.

Worry-free and secure management of your hoses

John van den Berg, product specialist industrial hoses & expansion joints, explains exactly what hose management at KLINGER entails. To ensure the operational safety of your company, hose assemblies in critical applications should be regularly checked for suitability. The more critical the application, the more frequent the checks are required. We help you systematically check, inspect and certify hose assemblies.

Avoid:

- Risk of exposure to chemical fluids

- Higher costs due to leakage

- Risk of inflicting damage to the environment

What we can do for you

- All your hose assemblies are tested in a timely manner.

- Your corporate security regarding hoses remains guaranteed.

- Certificates and documentation directly callable from online database.

- A wide range of high-quality hoses and expansion joints.

Cost savings through:

- Minimum chance of interruption to your production process.

- Reduced leakage costs.

- Less stock hoses needed.

Systematically inspect, test and (re)certify your hose assemblies.

Legislation

Funnily enough, in the Netherlands there are no concrete requirements yet on the control of hoses applied in the process industry. Strange in itself, considering that an unreliable or leaking hose can lead to catastrophic consequences. In various laws and regulations (such as the Dutch Working Conditions Act, NPR 5527, RI&E, Practical Guideline for Pressure Equipment) it is described that you have a duty to create a safe working environment and that you must take responsibility for causing damage to the environment. In short, no mandatory hose checks, but full liability in case of calamities. Reason enough not to let it come to that and to ensure yourself that all your hose assemblies are regularly checked and certified.

Inspection of your hoses

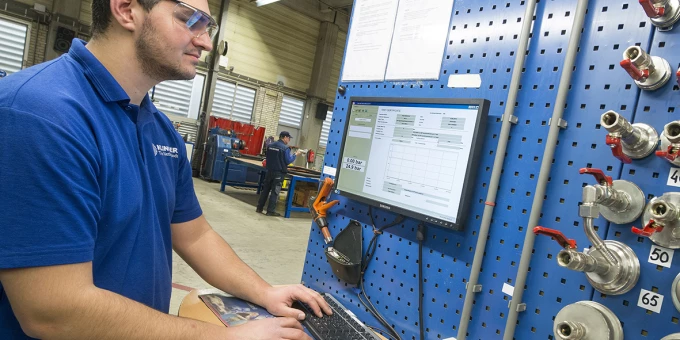

At our factory

In our fully equipped 'hoses inspection facility', we have a test bench with which all types of hoses are checked and inspected.

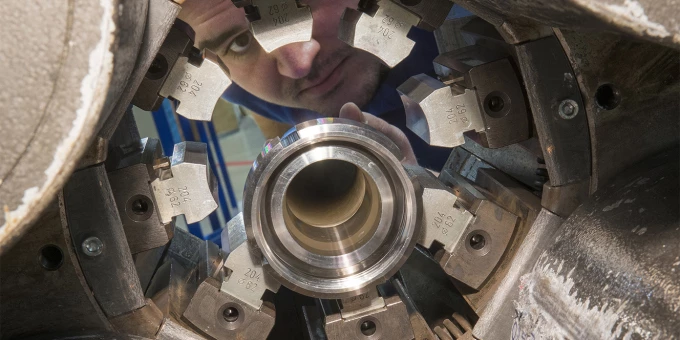

On-site

Our KLINGER hose testing team also comes to you. With our modern "on-site" testing facility, we inspect high-quality hoses and, if desired or necessary, make repairs immediately. This prevents the shutdown of your production process and increases operational safety. The work is carried out by our own specialized and VCA** certified service team.

In addition to the regular tests and inspections we carry out, we also have special equipment for endoscopic examination and carrying out measurements of electrical conductivity in accordance with EN-12115.

Hoses testing at our factory

On-site hoses testing

Overview of hoses verified in database

In our database we keep track of your periodic inspections and certifications. Using a login code, you can log into our database and thus have access to these documents at any time. Tested hoses are directly retrievable and easily reproducible with matching coupling or other accessories. If required, we will send you a periodic overview of the current status of your hoses. This overview includes information about the number (and type) of hoses you have in use, the lifespan per hose and the reason for rejection. On this basis, you can take preventive action. If a hose is rejected, you will receive, if desired, an offer for repair or replacement hose.

Roadmap hoses management system

- Inventory registration of your hose assemblies.

- Determining proper use of your hose assemblies.

- Consulting (use and type).

- Determination identification.

- Inspection and on-site testing.

- Unique identification (traceability).

- Evaluation test data.

- Exchange/return service via shuttle box.

- Interim periodic checks.

- Manage automated scheduling system.

For more information about our hose management, please contact:

Erik van der Plaat

Manager of E-business & Contract Management