|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Double Block vs. Double Isolation systems

Crucial to working safely in industry

08-04-2024, DBB and DIB in map

There is no arguing about safety. Maintenance and repairs to critical installations must therefore meet the strictest standards. And in this, both Double Block and Bleed and Double Isolation and Bleed play a crucial role. Not only do these valves ensure safety, they also contribute to a cleaner environment and a sustainable alternative for securing pipes.

What is Double Block and Bleed (DBB)?

Double Block and Bleed is a type of safety system in plants designed to separate two media that should not come into contact with each other. The bleed valve gives the process operator an indication of whether the block elements are working properly. A Double Block and Bleed is an important safety upgrade to the piping installation. Not only for technical personnel servicing or making adjustments to the systems, but also for the final product in the process, as it eliminates the risk of inadvertent mixing of media.

What is Double Isolation and Bleed (DIB)?

Double Isolation and Bleed is designed to allow safe working behind a valve, for example to block in a pipe when overhauling a pump. The Double Isolation and Bleed ensures that a pressureless space is created before a second block element and thus safe working is possible. In installations without such a solution, working on pipes is very risky, especially when using oxygen displacing media or hazardous materials. Double Isolation and Bleed has two different configurations, DIB-1 and DIB-2.

What are the advantages of Double Block and Bleed and Double Isolation and Bleed systems?

The great benefits of DBB and DIB systems often remain underexposed, despite their growing popularity. Many industrial organizations struggle to distinguish between the systems, leading a large number of professionals who do not deal with security issues on a daily basis to confuse Double Block and Bleed with Double Isolation and Bleed.

Fortunately, the number of companies in the Netherlands that consider safety a spearhead is growing. The thinking is simple: if affordable solutions are available to increase safety in the process, they should be implemented. The Netherlands is leading this global development, which is especially significant considering that many industrial plants in the country were built in the 1960s, a time when safety was not always a primary focus. Today, numerous companies are undertaking the conversion of these facilities to enhance safety and ensure a safer working environment.

In addition to ensuring human safety, there are other arguments that highlight the benefits of Double Block and Bleed or Double Isolation and Bleed:

- Better schedulable maintenance because with the Double Isolation and Bleed it is no longer necessary to run a complete installation "empty" for overhauls and/or cleaning.

- Cost transparency by making it more economical to install, for example, 1 pumping plant incorporating multiple block valves, rather than 3 or more stand-alone plants with their own valves.

- Strong risk reduction of environmental pollution because smaller parts of a plant can be taken out of service in case of leaks. This saves time and reduces production and energy losses.

What type of Double Block/ Isolation and Bleed are there?

There are numerous types of Double Block and Bleed and Double Isolation and Bleed systems available, depending on the physical situation and need:

A single model Double Block/Isolation and Bleed system

- Ball valve with 1 or 2 spring loaded seats and bleed valve.

- Lift-plug valve with bleed valve.

The advantages of a single model:

- Simple operation; two closure elements are closed simultaneously.

- Compact design, ideal in places in the installation where space is limited.

- The valves have full bore with uninterrupted flow opening and negligible pressure drop in the unit.

- Quick lock.

- Easily determine whether the system is safely isolated.

- Cost-effective.

The disadvantages of a single model:

- Small bleed connection.

- Closing elements not independently operable.

- System cannot be depressurized, drained or flushed via bleed valve.

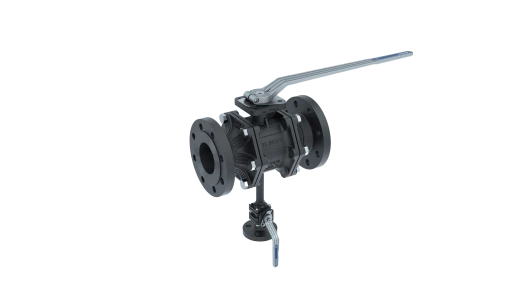

Double model Double Block/Isolation and Bleed system

- Two ball valves and a bleed valve in one housing.

- Two butterfly valves and a bleed valve in one housing.

- Assembly of three valves.

The advantages of a double model:

- Large(er) bore of bleed valve possible.

- The shut-off elements can be operated independently.

- The system can be depressurized, drained or flushed via the bleed valve.

- There are fewer leakage points because it is one structure.

Disadvantages of a double model:

- More actions in operation.

- The system can take up more space.

How are Double Block and Bleed and Double Isolation and Bleed valves placed?

How a Double Block system is placed in an installation depends entirely on local conditions and the nature of the process. This is always a matter of customization. The specialists at KLINGER do not limit themselves to an immediate solution to an acute problem, but look at all aspects in the production process - and especially at the people behind the systems and installations.

When designing a Double Block and Bleed or Double Isolation and Bleed, for example, the desired function must be considered. Consider:

- Double closure

- Double sealing with monitoring of both sealing elements

- Double seal with pressure release via bleed valve

- Flushing opportunities

- Block or separate media (DBB).

- Other possible special requirements (ATEX, SIL, etc.).

Examples of products with a DBB or DIB model:

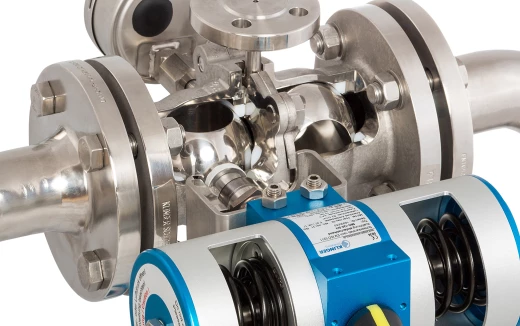

The KLINGER INTEC (and Pekos) DBB and DIB ball valve

- Version with single and double ball

- Standard build length

- Available in DIN and ANSI model

The KLINGER Ballostar ball valve DBB

- 2 spring-loaded locking elements and ball bearing

- Sealing elements function as independent seals

- When the ball is closed, the space around the ball can be depressurized with the blow-off valve.

- So this faucet has a full double block & bleed seal

ZWICK butterfly valves DBB and DIB

- 2 butterfly valves and 1 ball valve are built together in 1 housing

- Valves can be operated separately or coupled

Frequently asked questions (FAQ)

For more information on DBB and DIB, please contact: