|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Tightness testing for hydrogen gaskets

Tested gaskets ensure safety in hydrogen applications

26-02-2024, Benjamin Floegel on the material testing of KLINGER Dichtungstechnik

More and more operators of hydrogen systems are placing higher demands on the reliability of gaskets. KLINGER Dichtungstechnik offers manufacturers accurate specifications based on thorough testing procedures. Thanks to advanced testing methods, they can provide accurate details on the tightness of the products. This is an important advantage when selecting the right gasket for critical applications such as hydrogen, which involves a very small molecule.

To make flange connections "calculable," testing standards have been developed that outline ways to determine specific tightness characteristics. One of the most important standards is EN 13555, which describes tightness testing, including one that uses helium as the test gas at an internal pressure of 40 bar (580 psi). KLINGER Dichtungstechnik has already published many data sheets for its products, with characteristic values that can be used to calculate flange connections.

Of course, users and customers benefit greatly from information that gives them additional assurance when making their flange connections for hydrogen applications. This information includes, for example, the availability of reliable sealing properties to calculate specifications for safe hydrogen applications. To achieve this, KLINGER Dichtungstechnik has conducted a large number of EN 13555 tests at the mandatory minimum values for gasket compression with helium in-house, as well as commission tests with hydrogen at an external partner.

The following materials have been subjected to extensive testing:

- KLINGER®top-chem 2000

- KLINGER®top-chem 2000soft

- KLINGER®top-chem 2003

- KLINGERSIL®C-4240

- KLINGERSIL®C-4400

- KLINGERSIL®C-4430

- KLINGER®CompenSil

"Because we do not have the necessary equipment for testing with hydrogen and cannot perform measurements with this gas on site due to safety reasons, we outsourced the hydrogen testing to an accredited laboratory,"

- Benjamin Floegel, head of the materials testing laboratory at KLINGER Dichtungstechnik -

For each gasket material, four DN40/PN40 test samples were taken directly side by side from a sheet of sealing material. One gasket of each material was tested in the KLINGER test lab with helium at 10 and at 40 bar (145 to 580 psi). The other two gaskets were tested in amtec Messtechnischer Service's accredited test labs, also at 10 and 40 bar (145 to 580 psi), with hydrogen as the medium.

Testing with precision

The colorless and odorless inert gas helium has a similar atomic radius to the hydrogen (H2) molecule, which consists of two hydrogen atoms. Although helium, like the highly flammable H2, can pass through small openings and channels, it is harmless. Therefore, Benjamin and his team can handle it in their own laboratory and perform precision sealing tests. "To determine how KLINGER 's high-performance sealing materials behave with hydrogen under the same conditions, we conducted comparative tests on different KLINGER-sealing materials," Benjamin says. "When the results came back, we were pleasantly surprised because they were almost identical to the tests for helium."

Ahead of the competition

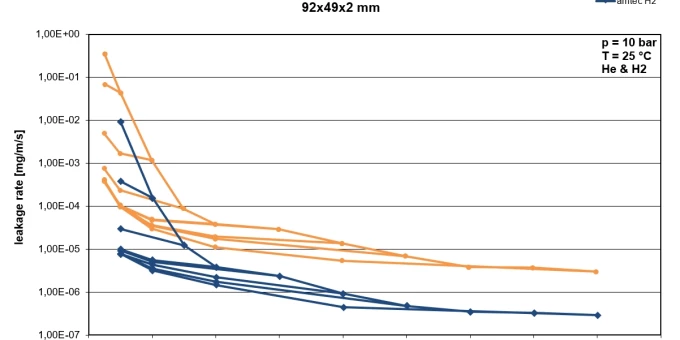

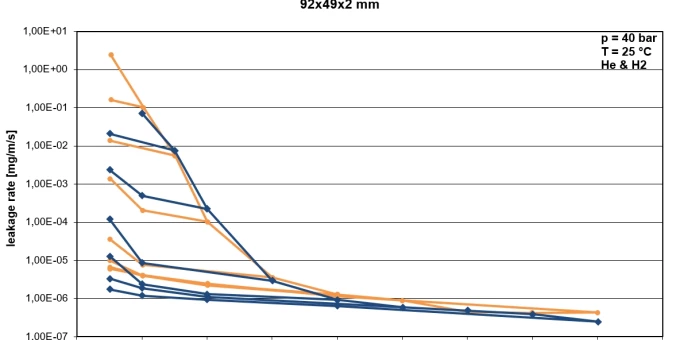

"For users and our customers, this means that flange connections for hydrogen applications can be designed using the existing density parameters for helium. That's a big advantage," Benjamin says. The graphs below show the similarity in measurements for helium and hydrogen.

The tests highlighted another advantage: all the KLINGER PTFE materials tested produced much better results at 10 and 40 bar (145 to 580 psi) hydrogen than in the equivalent tests with helium. This is clearly shown in the graph for KLINGER top-chem 2003:

With an increasing demand for applications with hydrogen, KLINGER Dichtungstechnik can now skillfully leverage its margin of experience. Reliable seals are an essential component in all sectors of industry - from the chemical industry to power generation to mobility.

Benjamin says, "Nothing is 100 percent leak-tight. But based on our results, we can now clearly demonstrate the leak-tightness classes that can be achieved at different compression rates with our products for hydrogen applications."

I have a specific question

Frequently asked questions (FAQ)

For more information on this topic: