|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Saving with circular heat

Making substantial climate steps? Invest in circular heat.

Reducing harmful emissions is quite a challenge for many industries.

One effective measure is to reuse the heat released from your production processes.

Let us inform you about Circular Thermal℠.

In three steps, we guide you intensively and effectively with the goal of making your production sites CO2 neutral

Saving up to 50% of your total energy consumption

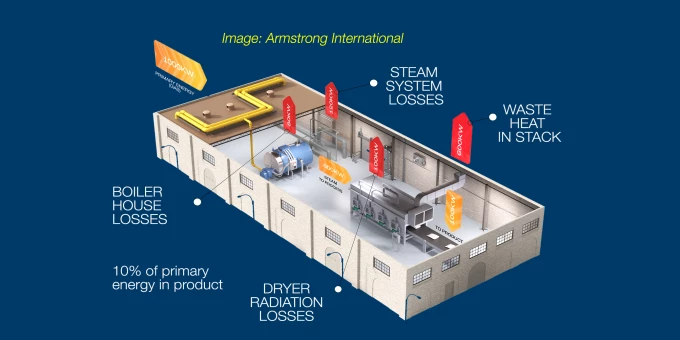

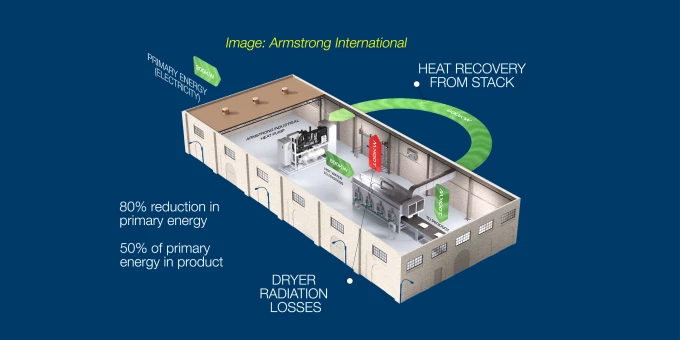

Your industrial processes and cooling systems give off a lot of heat, which is now being lost. We can link your heating and cooling systems together to recover this waste heat and reuse it in your industrial process. Based on research, 50% to 80% of the primary energy used in industrial applications leaves the plant as waste heat. Depending on your industry, the total energy consumption of your production facilities can be reduced by up to 50 percent.

For decades, we have been helping companies optimize their thermal processes. We do this together with our partner Armstrong International.

Route to carbon neutral production

1. Optimize

Making energy consumption as efficient as possible

2. Minimize

identify areas in your production process where you can save energy

3. Decarbonize

Reduce CO2 emissions in your primary processes to net zero

At each step, we can thoroughly explore where the opportunities lie for you. And it doesn't stop there. We are also happy to be of service to you afterwards. We can help you realize that potential.

Read more about these steps at armstronginternational.eu

Analysis of total potential savings

To understand the total potential for savings, it is necessary to map the entire heat management of the factories. We then look not only at the use of traditional facilities, such as gas, electricity, steam and cooling water, but also at the heat and cold contained in processes and products. This is a time-consuming and intensive exercise, but an investment that pays off.

Research on containment of heat consumption

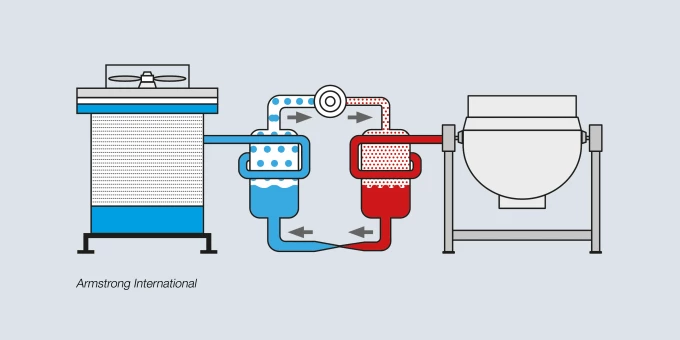

How can you minimize your heat consumption? We can also examine this precisely for you. In this study, one of the things we examine is the extent to which the residual heat available for your processes is sufficient. If not enough residual heat is available, it is possible to upgrade the waste heat with heat pumps.

High-temperature heat pumps

Achieving a CO2-neutral production environment often requires heat pumps. For over 50 years, Armstrong International and CombiTherm have had experience in the production of industrial heat pumps. That experience has led to a diverse range of reliable installations. These are heat pumps that are suitable for high temperatures up to 125 degrees Celsius and provide optimum efficiency. Combining a cooling and heating element can even double the return.

Video decarbonization methodology

Circular Thermal℠ is central to Armstrong's decarbonization methodology

ARMSTRONG INTERNATIONAL

OUR PARTNER IN STEAM AND CONDENSATE SYSTEMS

As a steam specialist with more than 100 years of experience, Armstrong offers a complete range of steam traps in various materials and with all possible connections. Non-standard applications can be solved with specially adapted steam traps.

TRAININGS AND EDUCATION

Knowledge of the system is crucial in order to safely produce as best as possible and detect problems early. Your staff must therefore not only have certain skills, but also keep up with developments in technology.

KLINGER and Armstrong offer courses and training to learn skills or increase knowledge. Our expert trainers have years of experience in steam systems. Training can be given at your location, or at our own training centers in Rotterdam, Elsloo or Herstal (B).

Feel free to contact one of our specialists:

Demian Nouwens

Product Specialist Energy Management, Steam Solutions