|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Cooperation Morssinkhof Plastics and KLINGER

KLINGER Is responsible for technical components

The right ingredients for an honest and long-term partnership

The relationship with Morssinkhof Plastics Emmen is a great example of personal attention and thinking along with the customer. And that is exactly what KLINGER stands for and how we distinguish ourselves. KLINGER is really on-site and we believe in long-term and honest relationships and providing long-term solutions that we support ourselves.

Problem Statement

The Morssinkhof factory dates back to the 1960s, and like many other factories of that era, it was built for a special function. This has worked very well, but in the meantime the pressure has been quietly increased to be able to produce more. Basic components such as steam systems have gradually been jacked up to meet the new capacities, but often this has not taken into account the connecting lines from utilities: how do steam and condensate relate to these new modifications? In short, as a production site, the plant is deployed to its utmost capacity, but the steam plant has not grown with it. All too often this leads to a chain reaction of problems: breakdowns, leaks, broken pipes and other unnecessary delays in the production process.

Solution by KLINGER

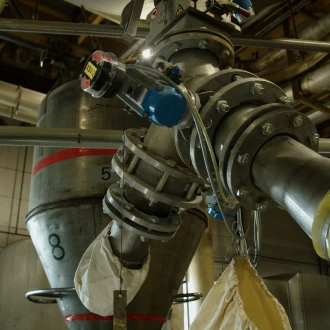

At Morssinkhof, they started upgrading their plant about seven years ago. KLINGER was already a supplier, but in this development, KLINGER supported in optimizing the process systems. Slowly but surely, KLINGER came more and more into the picture. It started with steam trap inspections and consulting. What sets us apart is that our Sales Engineer Marc Westerhuis visits the plant every Wednesday morning and thus continuously monitors the entire process together with the customer and advises optimization actions in consultation. He has been doing this since 2008. All the mechanics at Morssinkhof know this and collect issues so they can be discussed. They can show the problem to Marc, which of course is much more pleasant than having to discuss something over the phone. Also, Marc knows the customer's system from a to z and the KLINGER team can better assess which solutions will work best.

Meanwhile, all new valves are already supplied by KLINGER , ranging from valves (WTA) butterfly valves (Tomoe /ChemValve), the automation (Air Torque with A coating) and ball valves (Pekos manual). In addition to valves, we also supply gaskets, steam traps, loading hoses and expansion joints (rubber and stainless steel).

Watch the full video here

Since the emergence of the use of plastics in the 1960s and 1970s, Morssinkhof - Rymoplast has been the pioneer in plastics recycling. The company is one of Europe's largest producers of high-quality recovered raw materials and serves the European market, ranging from small companies in the plastics processing industry to the world's largest multinationals.

For more information about our services and services: