|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Unique installation for ARN diaper recycling

KLINGER Helps develop unique diaper recycling plant

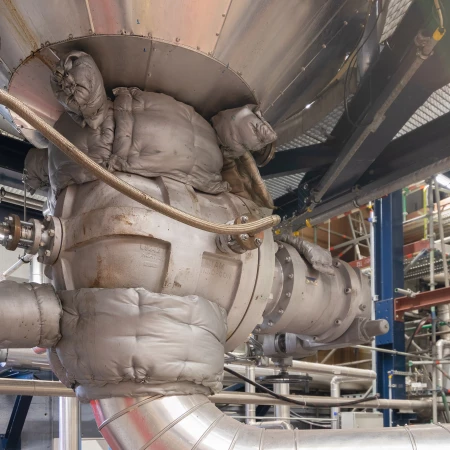

The waste-to-energy plant ARN B.V. in Weurt (NL) is the first to implement a sustainable way to recycle diapers and incontinence materials. KLINGER, the leader in sealing, fluid control and fluid monitoring systems, was involved in the project from the beginning, providing know-how and construction components.

Are diapers and incontinence materials really such a waste problem? Yes, but not for long! At least not in the Netherlands. Dutch waste management company ARN has found a way to turn used diapers into a resource. For the physical implementation and for help with the technical challenges, ARN called on the specialists at KLINGER.

"Diapers used to be burned, but now we can recycle them. Diapers are broken down into plastic, fertilizer and green gas. That way we can achieve a huge CO2 reduction."

- Rutger Jan Pessers, director at ARN Weurt

CO2 reduction

The new diaper recycling method saves 964 kg of CO2 equivalent per ton of diaper material treated compared to conventional incineration.

For ARN, this means

a reduction of 14,460 tons of CO2 per year when the expansion is completed in 2021.

KLINGER Provides expertise for groundbreaking invention

Although KLINGER The Netherlands has vast experience in all kinds of industrial production, they had no reference to compare this new challenge to. "However, our technical expertise allows us to adapt to any production process. After all, it's just applied physics. In our business, we need to be able to calculate the ideal specifications, no matter how complex the requirements are. Heat, pressure, corrosion, flow rate, type and aggressiveness of media, etc. - everything must be taken into account when choosing and designing the right product," says Boudewijn Slager, product specialist fluid control at KLINGER The Netherlands. KLINGER worked intensively with ARN's engineering department and project management to discuss the specific process requirements, provided them with the design specifications and also helped with calculations and estimates.

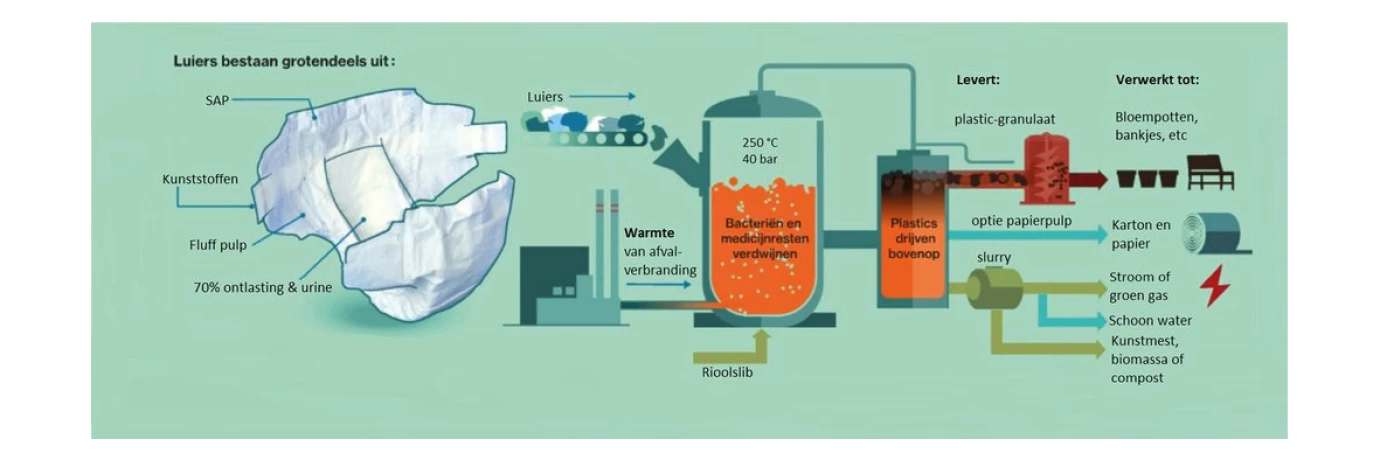

In this pioneering process, Dutch waste processor ARN separates diapers and incontinence materials into their components, which are then recycled and fully reintegrated into a circular economy.

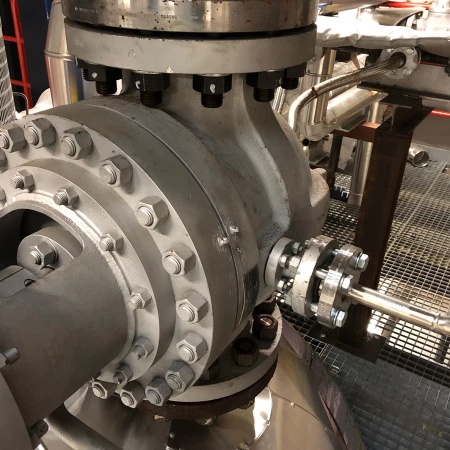

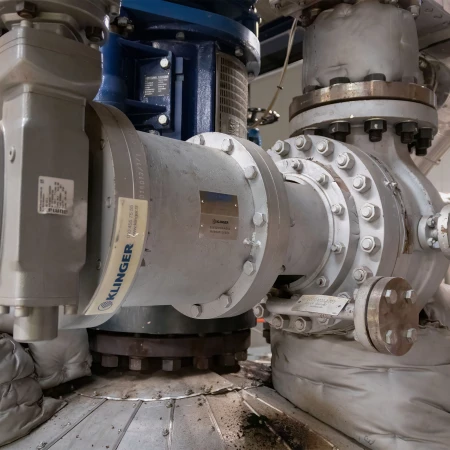

Finding the right valves for hot steam, high pressure and harsh conditions

Diapers consist of plastic, paper and biodegradable waste and often contain some problematic substances such as pharmaceuticals. The idea was to melt the diapers with 250°C steam, extract the plastic for recycling and use the remaining components for biogas and fertilizer. There were many unknown factors: What type of piping is safe to transport the steam? What valves can withstand the extremely high pressure required? How can we keep the pipes free of molten and congealing plastic? KLINGER The Netherlands provided not only a lot of know-how but also the appropriate technical components such as various valves (control valves, ball valves, butterfly valves and specially designed 'lift plug' valves), steam traps, gaskets and hoses.

"Helping our customers improve their industrial processes is our daily work. But this job is special. Everyone knows about diapers, but few think about the effect of discarded diapers on the environment. I'm proud to be part of this groundbreaking project."

-Boudewijn Slager, fluid control product specialist at KLINGER The Netherlands

Did you know?

Diapers, especially those used by the elderly, contain many drugs, making them a danger to groundwater. During the process invented by ARN and the Dutch engineering company Elsinga Policy Planning and Innovation, the diapers are broken down into their individual components. The plant's output is almost completely free of pharmaceutical substances.

KLINGER The Netherlands not only provided a lot of know-how, but also supplied ARN with suitable technical components such as valves, control valves, steam traps, gaskets and hoses.

Boudewijn Slager and Klaas Doting (with the white helmets) of KLINGER The Netherlands guided ARN from the beginning with on-site expertise. Niek Temmens (red helmet), process operator at ARN, operates the system.

This unique process is ready to share with the world

The process was tested in a small pilot plant on 80 kilograms of diapers. By the fall of 2019, the first of the three large reactors was ready. This reactor can process 5,000 tons of diapers per year. ARN plans to expand the plant and process 15,000 tons per year - good for 75 million diapers. ARN's inventive diaper recycling process has now been approved by the RIVM and is also receiving subsidies from the EU. Soon this process will be ready to share with the world. "This is the first such process anywhere in the world and there is already a lot of interest in it. If it proves to be a success, I am sure it will be applied in many places," said Klaas Doting, Sales Engineer at KLINGER The Netherlands. Elsinga handles international sales of its patented process.

Frequently asked questions (FAQ)