|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Green hydrogen is the energy source of the future

Power-to-X: Green hydrogen is the energy source of the future

KLINGER Germany - Power-To-X - Sealing solutions for the hydrogen market: ✓ Global hydrogen initiative ✓ Infographic on green energy ✓ Interview with Norbert Weimer

KLINGER expert, Norbert Weimer, knows how hydrogen energy can help in the fight against climate change. In our factcheck, he also explains what sealing solutions KLINGER has in store for the hydrogen market.

"Only with green hydrogen energy will we be able to make the necessary energy transition. Hydrogen is the oil of the future!"

This is the development of which Norbert Weimer, manager of KLINGER Germany, is convinced. And he is not alone: many scientists, politicians and economic experts worldwide predict a turnaround to green energy in which hydrogen is the key technology.

Global hydrogen initiative

Austria's Chancellor, Sebastian Kurz, wants to make Austria a "hydrogen nation". And in Germany, too, a national hydrogen strategy is paving the way for the large-scale use of this energy source. Across Europe, 150 similar projects are being funded. And for the first time, China has also included hydrogen development in its 2020 national development plan. Under that plan, the Chinese government is now funding hydrogen refueling stations in the country. Consequently, the stock prices of hydrogen shares are on the rise. In fact, share prices were immune to COVID-19.

Hydrogen - opportunities, challenges and solutions; KLINGER Interview

About expert Norbert Weimer, manager KLINGER Germany

Norbert Weimer is manager of KLINGER GmbH in Germany. KLINGER GmbH is a member of the working group Power-to-X for Applications established in 2018 by the Association of the German Mechanical Engineering Industry (Verband Deutscher Maschinen- und Anlagenbau). Companies such as Siemens, MAN and Thyssen Krupp are also in the working group.

Where do you see the main applications for hydrogen in the future?

In fueling commercial vehicles such as trucks, buses and trains. There are also industrial applications in chemistry and steel production, for the reduction of iron oxide. And hydrogen can be used for e-fuels such as gasoline, kerosene or diesel, for example, to power aircrafts.

In what areas is hydrogen already being used as an energy source today?

Currently, the use of hydrogen as an energy source is still limited. It is used in welding, as rocket fuel, in fuel cells and, in rare cases, as automotive fuel. Throughout Europe, there are about 140 stations where hydrogen can be refueled.

Hydrogen is also a chemical feedstock for ammonia production and is used for gas packaging (E949) and food preservation. In addition, refineries need large quantities of it for hydrogenation.

What are the main challenges in hydrogen handling and what solutions does KLINGER offer ?

Hydrogen molecules are extremely small, even smaller than those of helium. Thus, they escape easily through porous material. Therefore, leakage is a bigger problem than with other substances. Moreover, like other flammable gases, hydrogen is flammable and explosive when in contact with oxygen and a tiny spark. We have developed products that address these problems:

- additional high-quality products

- high leak-tightness

- high assembly quality

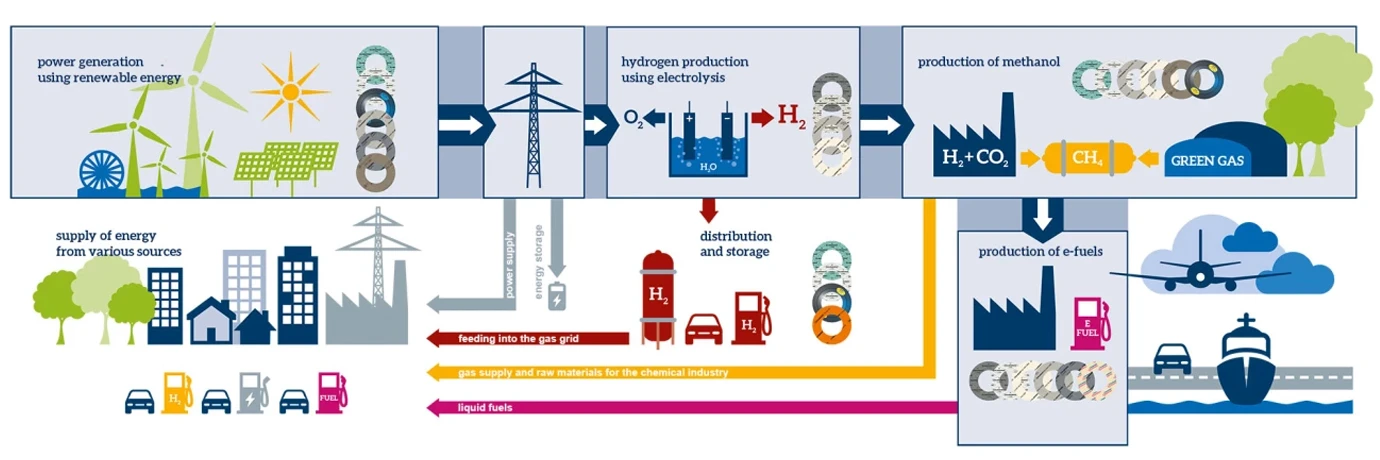

Power-to-X: Using green power where and when it is needed

Power-to-X (also P2X and P2Y) combines all available options for using excess power from renewable energy sources.

So what are the benefits of hydrogen now? Why the hype? The strong point is the versatility of hydrogen. Compared to electricity, it can be stored more easily. Therefore, hydrogen is the ideal medium for storing seasonal surpluses of wind, water or solar energy that can later be used as a source of energy or an auxiliary source for industrial processes. Experts call this transfer of CO2-neutral energy "Power-to-X" (P2X).

Sector linkage as a global mission

When green power is converted to other energy sources, P2X allows electricity to be used independently of power sources such as wall outlets, for example, to power vehicles, aircraft and ships. Experts speak of "sector coupling" when the power needs of different sectors are coupled through the medium of hydrogen and its successor products.

Sustainable circular economy using hydrogen

Thus, the flexible use of hydrogen can contribute to the energy transition. But some challenges still await us on the road to model this ambitious concept. First, the infrastructure needed to transport large quantities of this highly volatile and extremely light gas is still lacking. Studies are currently underway on how hydrogen, as an additive to petroleum gas, can be transported through gas pipelines to reduce CO2 emissions during combustion.

If green hydrogen is produced in countries with abundant solar and wind energy, it can be converted there into methanol or e-fuels, such as gasoline, kerosene and diesel, and then transported conventionally. This would be an opportunity, for example, to make air transport climate-neutral. Sector coupling is thus a global task.

Hydrogen

Hydrogen is a molecular gas with the chemical notation H. On Earth, it is bound to water. Consequently, it is part of almost every organic compound. Water is formed when hydrogen reacts with oxygen. And because the reaction is exothermic (produces heat), energy is a byproduct.

Gray hydrogen →

is obtained from fossil fuels such as petroleum gas or coal. CO2 is then released into the atmosphere and contributes to the greenhouse effect. An example: The production of one ton of hydrogen releases about ten tons of carbon dioxide. The production of hydrogen from fossil fuels is still the most common production method today.

Blue hydrogen →

is gray hydrogen whose CO2 is separated and stored during production (CO2 capture and storage). It is stored in underground caverns or further processed as a feedstock in the chemical industry. No CO2 is released into the atmosphere during this process of hydrogen production. Thus, this process can be considered CO2 neutral.

Turquoise hydrogen →

is a byproduct of the thermal decomposition of methane. The condition for the CO2 neutrality of this type of hydrogen is that the required high-temperature reactor is powered by renewable energy and that solid carbon is produced instead of CO2.

Green hydrogen →

is produced with 100 percent renewable electricity and is thus truly carbon neutral.

Hydrogen + oxygen = energy

Like electricity, hydrogen is not a primary energy source that can simply be mined and used. Hydrogen must be produced, which requires a certain amount of energy. Depending on the energy source, hydrogen is classified on a colored scale.

Sustainability

Hydrogen is only truly green if the electricity used to produce it is also green. If fossil fuels such as petroleum gas or coal are used, the synthesis still releases CO2. If the energy needed to produce hydrogen is green, hydrogen can be used as a completely CO2-neutral energy carrier.

Safe handling: elastomeric, PTFE and fiber reinforced gaskets

KLINGER-products make the transport, storage and further processing of hydrogen safe. With elastomeric, PTFE and fiber-reinforced gaskets from KLINGER, it is possible to keep the joints of construction elements leak-tight and impermeable, even for extremely small hydrogen molecules (see Interview with expert Norbert Weimer).

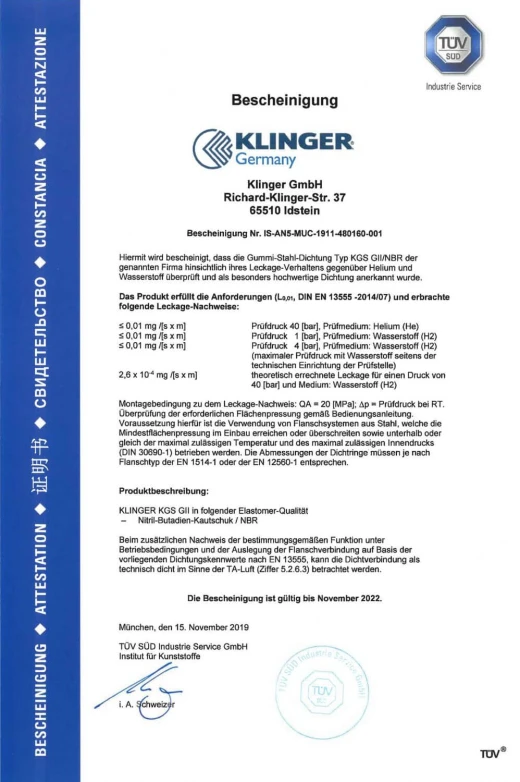

KLINGER Germany TÜV certificate

Of course, all gasket types are adequately tested and inspected by the German TÜV, because leak tightness is essential when handling hydrogen. After all, hydrogen can ignite within seconds when it comes into contact with oxygen and a spark (see Knalgas). To avoid this, the highest quality and safety standards must be adhered to: "KLINGER has the expertise to accompany and implement the new P2X technologies with the appropriate sealing technology," says Weimer.

All KLINGER gaskets have been tested by TÜV for their leakage behavior with hydrogen and are recognized as particularly high-quality seals. TÜV stands for Technischer Überwachungsverein, the German technical-testing body. TÜV is one of the largest testing organizations in Germany for performing safety checks, mostly as required by state laws and regulations.

Did you know that ...

... the French writer Jules Verne predicted back in the 19th century that hydrogen would one day become a source of energy? In his novel "The Secret Island" (published in 1874), he wrote: "I am convinced that one day water will be used as a fuel, that the constituents hydrogen and oxygen will become the source of heat and light. Water is the coal of the future!"

Product offerings for the industry and technology sector

Products for cutters and the technology sector are already available (see KLINGER 's product catalog for P2X). The experts at KLINGER, like Weimer, look forward to explaining their know-how in direct discussions with customers: "The close cooperation in the entire distribution channel, from the manufacturer through the cutter to the plant manufacturer and operator guarantees safe, efficient and durable sealing solutions in the hydrogen industry."

Power-to-X

Power generation using renewable energy

Gaskets for steam and water turbines with inlet and outlet lines and as corrosion protection between tower segments of wind turbines.

- KLINGERSIL® C-4400

- KLINGERSIL® C-4430

- KLINGER KGS G II

- KLINGER®top-chem 2000

- KLINGERgraphit

- KLINGER Mica laminate

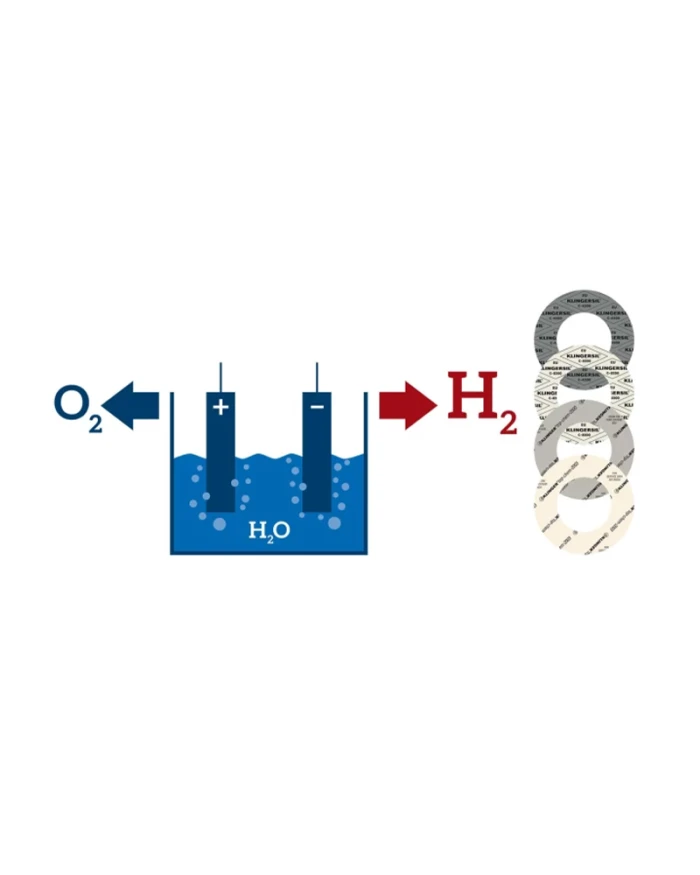

Hydrogen production by electrolysis

Standard gaskets and housing seals in systems for electrolysis of alkaline and acidic compounds.

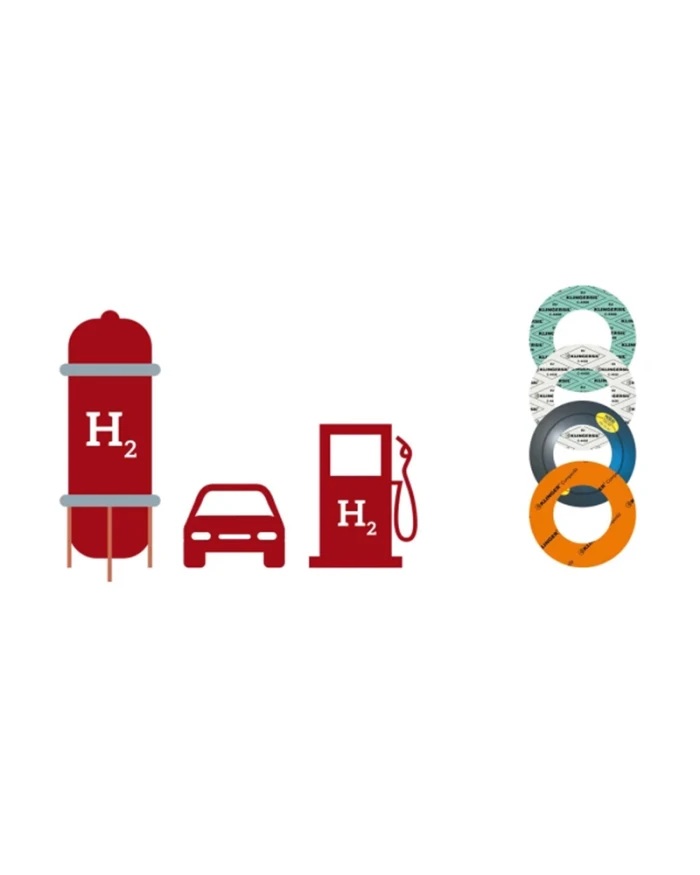

Distribution and storage

Gaskets for tanks and pipe networks and for gas storage systems in caverns for gaseous and liquid physical states.

- KLINGER KGS G II

- KLINGERSIL® C-4400

- KLINGERSIL® C-4430

- KLINGER CompenSil

Production of methanol

Production of methane, methanol and long-chain hydrocarbons. Conversion processes in reactors using catalysts and gas cleaning systems. Gaskets adapted to process and temperature.

- KLINGER KGS G II

- KLINGERSIL® C-4400

- KLINGERSIL® C-4430

- KLINGER®top-chem 2000

- KLINGER®top-chem 2003

- KLINGER Mica laminate

Production of e-fuels

There are several processes for producing e-fuels (Fischer-Tropsch, Sasol, etc.) that work with catalysts in the medium to high temperature range.

- KLINGER KGS G II

- KLINGERSIL® C-4400

- KLINGERSIL® C-4430

- KLINGER®top-chem 2000

- KLINGER®top-chem 2003

- KLINGER® Quantum

- KLINGERgraphit

KLINGER-gaskets and their application spectrum for hydrogen and P2X steps:

Elastomeric gaskets

With standard flange connections and fairly low temperatures for gas supply, distribution and storage. The German Institute for Gas and Environmental Technology (DBI GUT) and the German technical-testing body TÜV Süd have found hydrogen to be positive and certified as a storage medium.

Graphite laminate packaging

For high temperatures in the plant, e.g. above 200 °C. Wherever hydrogen is converted into e-fuels (gasoline, kerosene, diesel) and the process includes liquid phases.

Fiber reinforced gaskets

Are used in gas distribution, in machines and plants such as electrolyzers and process engineering plants, as well as in pumps. They are also supplied in non-standard sizes - the advantage: fiber reinforced gaskets can be produced as flat gaskets in any size and shape. They are also certified for use with hydrogen by the German Institute for Gas and Environmental Technology (DBI GUT) and the German technical inspection authority TÜV.

PTFE-based gaskets

These sealing materials from KLINGER are suitable for all steps of the P2X process up to temperatures of 250 °C. They are characterized by high chemical stability and high leak-tightness with gas, and they do not wear out in use. They are also certified by TÜV for use with hydrogen.

Frequently asked questions (FAQ)

For more information on seals for green hydrogen: