|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Safely applying geothermal energy - together with KLINGER

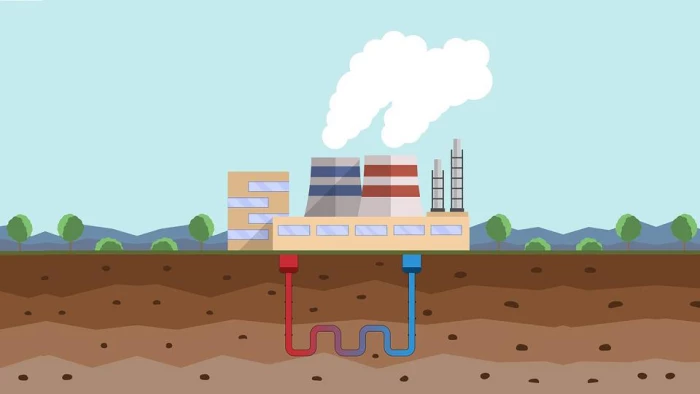

Geothermal Energy

Safely applying geothermal energy - together with KLINGER

- Reliable and safe for people and the environment

- High quality products

- Thoughtful and solid solutions

Using geothermal energy reliably and safely

Geothermal energy is seen as key in the matter of the energy transition. The Netherlands and many other countries are looking for systems where dependence on fossil fuels and CO2 gas emissions are reduced.

The Netherlands' goal is to have a completely sustainable energy supply by 2050. The future is a hybrid form in which various climate-neutral energy sources will find a place. Because the demand for energy can vary greatly, energy sources are also needed that are not dependent on external factors, such as sun or wind. Geothermal energy, extracting energy from the the earth, is not dependent on weather, wind or season. Geothermal energy is therefore a predictable and reliable source of heat.

Geothermal or geothermal energy is sustainable thermal heat from the earth's crust which can be used to heat buildings, homes, greenhouses and industry. The deeper the heat is extracted, the higher the temperature of the naturally occurring geothermal water. Once pumped above ground, the heat is used and then the cooled water is returned to the same layer of earth after which it warms up again.

Geothermal plants produce 24/7 under challenging conditions and strict safety requirements. This requires reliable and safe high-quality products that meet international standards.

KLINGER offers a wide range of products for for the Geothermal industry, such as appendages, seals, hoses and expansion joints that meet the stringent requirements and guidelines of this industry: robust and in corrosion-resistant and wear-resistant versions. This specialized industry faces demanding customers and stringent regulations regarding safety, procedures and certifications. Geothermal installations require reliable, sound, durable and safe solutions.

KLINGER distinguishes itself through product specialization. We have product specialists, each with their own discipline. Experienced and committed technicians who are educated and trained by the suppliers and manufacturers of the systems in question. They know the ins and outs, the do's and don'ts of their product in the production process. Solving complex issues is their passion.

KLINGER SYSTEMS SUITABLE FOR GEOTHERMAL ENERGY

-

CABLE CRANES

-

BUTTERFLY VALVES/VALVES

-

FLANGE GASKETS

-

COMPENSATORS

CABLE CRANES

KLINGER BALL VALVES TYPE BALLOSTAR® KHA

- Unique sealing system with spring-loaded sealing elements enclosed by stainless steel.

- Equipped with ISO 5211 top flange for easy mounting of a control unit.

- Provision for locking.

- SIL2 IEC61508.

These ball valves are commonly used in:

- Pumping Stations

- CHP plants

- Steel mills

- Hydropower plants

- Steam Systems

KLINGER BALL VALVES TYPE BALLOSTAR® KHI

These ball valves are commonly used in:

- Underground pipe tunnels

- Underground spaces for district heating

- Pumping Stations

- CHP plants

- Steel mills

- Hydropower plants

- Tunnel drills

- Steam Systems

BALL VALVES TYPE INTEC

ZERO EMISSION, OPTIMUM PROCESS SAFETY, LESS MAINTENANCE

These ball valves are commonly used in:

- Chemical industry

- Double block & bleed solutions

- Applications with high switching frequencies

- Special designs, metal sealing, free outlet

With the range KLINGER INTEC ball valves, KLINGER brings a complete program of ball valves for application in the chemical industry. The innovative design has been achieved through years of experience and specialist knowledge.

With the range KLINGER INTEC ball valves, KLINGER brings a complete program of ball valves for application in the chemical industry. The innovative design is the result of years of experience and specialist knowledge. One of the distinguishing features of the design is the unique maintenance-free stem sealing which is certified according to TA-Luft / VDI 2440. The ball valves are completely designed, produced and tested according to the current Euro standards and meet all the strict requirements of the chemical industry. Besides standard ball valves according to DIN or ASME with PTFE seals, the INTEC range includes a wide range of ball valves for heavier applications, such as ball valves with metal seats, ball valves with free outlet without dead space, ball valves for high pressure application, multi-way ball valves etc. The ball valves are also available custom made.

BUTTERFLY VALVES / VALVES

BUTTERFLY VALVES TYPE ZWICK TRI-CON

High quality butterfly valves for heavy duty applications

These butterfly valves/valves are commonly used in:

- Demanding industries on applications ranging from oxygen to flue gases,

- From cryogenic to superheated steam

- Many chemical processes.

TRI-CON valves from ZWICK have proven over the years to be reliable, safe and durable. Some of the applications where the these valves are successfully used are:

Refineries

desulphurization systems and tail gas treaters / steam / ESD solutions (emergency shut down) in storage of oil and refined products / hot cracking gas / flare gas / blocking pumps

Petrochemicals

inblocking propylene plant equipment / oxygen & hydrogen / ethylene cracking plants / PSA & molecular sieves switching valves / flare Isolation / CO2 / butadiene & styrene plants

Offshore

fire extinguishing systems / CO2 switching valves / crude oil insulation

Energy

steam/condensate/boiler feed water/blocking pumps/fuel gas

Pulp & Paper

lime & slurries / steam / boiler feed water / green, red & black liquor

Food

hot water / steam / condensate

Chemistry

syngas/nitrogen/acids

Steel industry

hot water / steam / condensate / blast furnace gas / cooking gas / oxygen / hot air / cooling water

Seals | gaskets

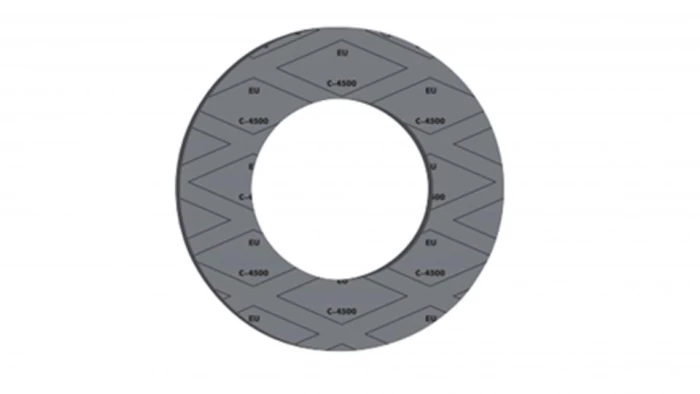

FLENSION FITTINGS Type KINGERSIL®C-4500

CARBON FIBER WITH NBR

These seals / gaskets are commonly used in:

- oils

- alkalis

- hydrocarbons

- many gases

Characteristics:

- Universal use.

- Good resistance to alkaline.

- Available from our own production in plates, rings and windows.

Certificates KLINGERSIL®C-4500:

- DIN DVGW

- BAM II-1734/2004

- TA-LUFT (clean air) acc VDI2440

- Germanischer Lloyd cert.

- ÖVGW

- BS 7531 Grade AX

- "Fire safe" EN 10497

- KTW drinking water

- RoHS cert. 2011/65/EC

- 2003/11/EC cert.

- 76/769/EWG cert.

- Biofuels tested 2003/30/EC

- Reach statement

- SVHC list statement

- ÖVGW certificate

FLENSION FITTINGS Type KLINGER TOP-CHEM®2000

HIGH-QUALITY SEALING MATERIAL BASED ON PTFE

Suitable for:

virtually all applications up to 260ºC, including acidic and alkaline media and steam

Features:

- High flow resistance.

- Wide deployment area.

- Very suitable as plug or thread gasket due to low friction and high strength.

- Fire-safe.

- Does not adhere to the flange.

- Material does not age.

- Available from our own production in plates, rings and windows.

Certificates KLINGER TOP-CHEM®2000:

- DIN DVGW approval

- BAM II-2629/2004 IV

- DIN DVGW W270

- TA Luft (clean air) acc VDI2440

- "Fire safe" API 6FA and DIN EN ISO 10497

- KTW, WRC certificate

- FDA compliant statement

- Germanic Lloyd label

- US Coast Guard

- Registro Italiano Navale

- Det Norske Veritas AS

- RoHS cert 2011/65/EC

- 2003/11/EC cert.

- 76/769/EWG cert.

- Reach statement

- SVHC list statement

Expansion Joints

KLINGER STAINLESS STEEL COMPENSATOR

WITH INNER SLEEVE

These expansion joints are mostly used in:

- (petro)chemical industry

- cogeneration plants

- shipbuilding

The metal expansion joints from KLINGER are designed, manufactured and tested according to the criteria of the Expansion Joint Manufacturers Associations, or EJMA standardization for short. They are used for absorbing thermal expansion, reducing vibration and for stress-free arrangements in piping systems in a wide variety of process technologies.

Our services to perfect your process technology together

For more information about our geothermal products and services, please contact: