|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Energy Efficiency Directive (EED) - KLINGER helps

Saving energy, KLINGER knows how.

Our specialists are happy to help!

The government has established guidelines on how you can comply with Energy Efficiency Directive. Within this established list of recognized measures are items that KLINGER can help you with. Our product specialists will be happy to advise you on several possibilities for achieving energy savings within your company. We understand better than anyone that an investment involves costs. That is why we are happy to calculate the payback period of your investment. Often this time is shorter than expected and in many cases you will even earn money within the foreseeable future!

4 tips to save energy:

1. Steam and condensate system

Optimize your steam and condensate system

In addition to energy savings, benefit from:

- Lower fuel costs

- Increased security

- More reliable systems

- Reduction of CO2 emissions

- Less downtime

- Service life improvement

- Rising and stable production

- Shorter batches

- Reduced consumption

- Lower maintenance costs

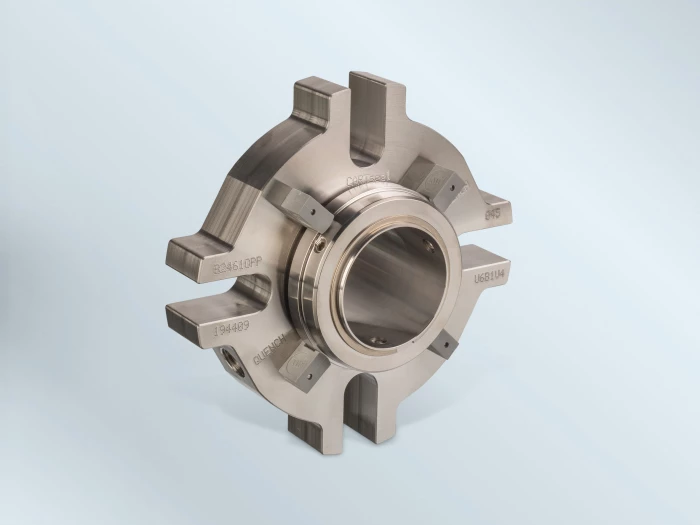

2. Mechanical seals

Installation of energy-saving mechanical seals in pumps

Did you know that about 85% of pump seals leak prematurely? Therefore, prevent unnecessary emissions. Leaks mean loss of production and energy and are potentially harmful to people and the environment.

By using Latty's mechanical seals your pumps will run leak-free again and the energy consumption for your pumps will also decrease. Get advice from one of our KLINGER Product Specialists and see what you can save!

3. Flange seals

Using the right gasket prevents leakage and pressure loss.

After we have audited your flange connection and the materials used, we advise you on which locations you can achieve a quick-win. All our gasket materials meet all legal requirements.

A good flange connection consists of more than just a good gasket. The assembly of these products is also true craftsmanship. With our Flange connection training course we teach you / your team the methods for achieving an optimally functioning flange connection and preventing unnecessary energy loss.

4. Butterfly valves

with a low breakaway moment

Save energy and lower maintenance costs without major changes to your installation?

The innovative design of the Tomoe butterfly valve ensures smooth opening and closing, resulting in much less energy consumption. In addition, the service life of this valve is considerably high; meaning less downtime of your process for repair or replacement!

For questions on this topic:

Demian Nouwens

Product Specialist Energy Management, Steam Solutions