|

Rotterdam

KLINGER The NetherlandsNikkelstraat 2 3067 GR Rotterdam

Elsloo

KLINGER Service Center LimburgBusiness Park Stein 208A 6181 MB Elsloo

Velsen-Noord

KLINGER The NetherlandsRooswijkweg 200 1951 MD Velsen-Noord

Moordrecht

Hadro TechnologySouth Lane 351 2841 MD Moordrecht |

Metal hoses

Metal Hoses

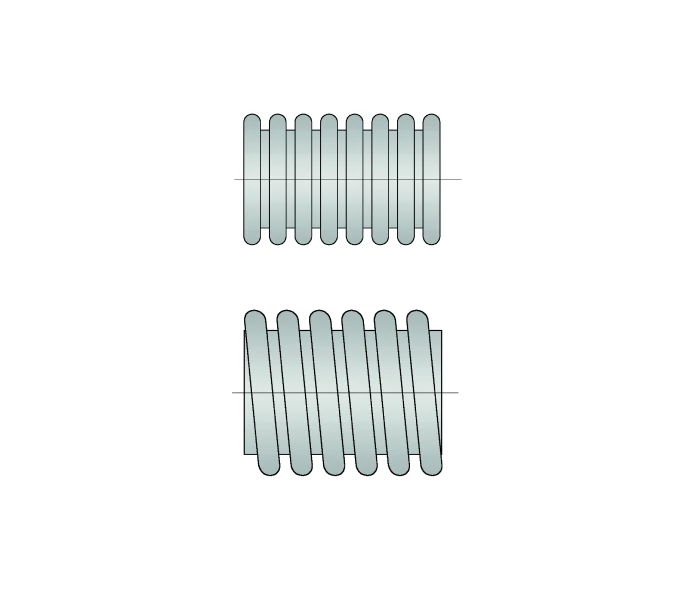

These hoses are constructed from a stainless steel band. They are rolled into the shape of a tube and butt welded longitudinally. Then the tubes are mechanically or hydraulically deformed into spiral or parallel corrugated hoses. These are the two basic shapes of corrugated metal hoses.

The flexibility of the hoses is determined by the overall wave configuration, viz:

- Large wave height: flexibility increases with higher wave height.

- Small wave spacing, many waves per linear meter.

- The flexibility is proportional to the number of waves per unit.

- The wall thickness: a thinner wall gives great flexibility but at the expense of the compressive strength of the hose.

- The waveform: an omega shape that gives greater flexibility than the more straight shape.

The great advantage of the parallel corrugated hoses is that they are not subject to torsional forces created by pressure shocks and pulsations.

Applications

- (Petro)chemical industry

- Steel Industry

- Oil and gas

- Energy and district heating

- Pulp and paper

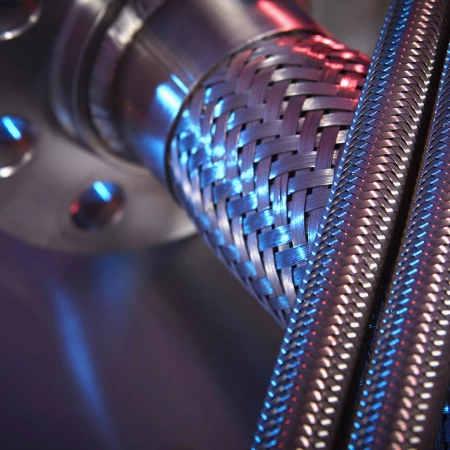

Therefore, metal hoses from KLINGER

- High security

- 1, 2 or 3 braids

- In accordance with European standards

- Certified welded

- Fast delivery

Options

- Version with insulation, anti-kink, tracing, etc.

- Lots of material types

- Smooth hooked model for granules, among other things

To be used at:

Temperature: 200°C to 600°C

Pressure: 1 to 200 Bar

Diameter: DN6 to DN300

Two types

In both types, the distance between two waves can be large or small,

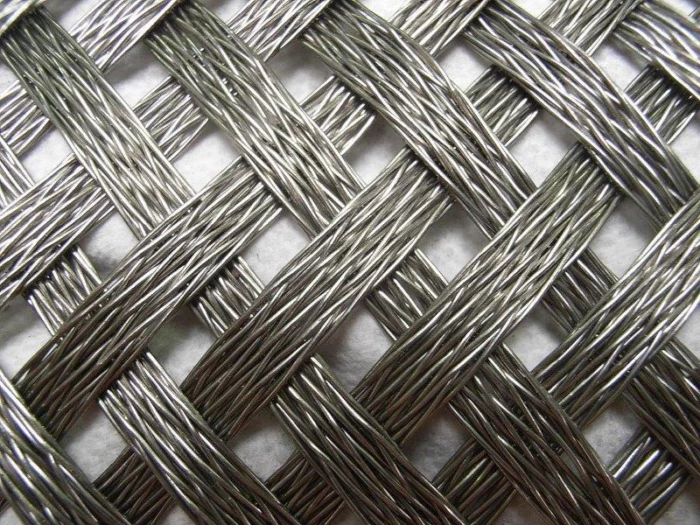

so that one speaks of widely or narrowly corrugated hoses. The pressure resistance of a hose is determined by the stainless steel braid. The number of braids varies from 1 to 3. However, the braid also absorbs the reaction force created by the internal pressure. The number of braids determines the maximum internal working pressure of the hoses, as well as the test and burst pressure. The safety factor is applied between working pressure and burst pressure and is 4.

Parallel corrugated

Here the waves lie side by side as parallel rings so that each wave is perpendicular to the axis of the hose.

Spiral corrugated

The wave is not perpendicular to the axis of the hose. The line from the top of the waves is a spiral.

For more information about our metal hoses, please contact: